FEATURES

• UV-STABILISED POLYETHYLENE – Rotationally moulded to form a tough, 12.7mm thick body. Prior to moulding, colour pigment is blended into polyethylene material eliminating the need for costly sandblasting and continued painting. Through a unique mould design and a controlled process, an increased thickness is formed at major stress points. This polyethylene material will also repel marine growth.

• DIVIDED INTO THREE SECTIONS – A float section, middle superstructure section and top section form an abrasion resistant, shock absorbing buoy able to withstand knocks and/or collisions. In event of damage, individual sections can be easily replaced on the deck of a buoy tender, at sea.

• MATCHING OR ALTERNATING SECTIONS – Bifurcation buoys can be easily made, either red or green as needed. Cardinal buoys can be assembled using the same method with yellow and black sections. Fairway or Safe Water buoys are produced using a process of moulded in colour graphics, resulting in red and white vertical striping.

• 2.5 METRE DIAMETER FLOAT SECTION – Utilises 316 stainless steel tube ‘skeleton’ to support (4) 1/4 float sections with 12.7mm thick walls. These unsinkable sections are filled with polystyrene beads. The float sections are then sealed and placed into a steam-chest to expand the foam beads to maximum size, fusing the beads together. This process results in one solid piece, completely filling all voids, preventing water ingress in the event of puncture, adding toughness to an already rugged floating aid.

• POWER – Eight (8) AGM spill-proof batteries configured for 12 volts are housed in middle superstructure section. This section includes a hinged, tamper-proof, watertight service hatch.

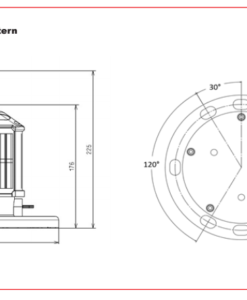

• NAV AID TOP SECTION – This section can support (4) 90 watt solar modules. Configurations of solar modules can vary depending on electrical load and average solar insulation for area of deployment. An internal high gain passive radar reflector (10m2 ) and hard-anodised aluminium lantern guard, if needed, are also included. All additional internal optional equipment is also fitted into this section.